Introduction

In the world of the automotive repair industry, paintless dent repair (PDR) stands out as a cost-effective and efficient solution. To meet the demands of discerning customers and stay ahead in the competitive market, skilled PDR technicians are constantly seeking ways to take their craft to the next level.

This article delves into the realm of advanced tools and techniques that can elevate the art of paintless dent repair, enabling technicians to achieve flawless results and exceed customer expectations.

Paintless Dent Repair (PDR)

I. Mastering Advanced Tools for Precision

Taking PDR to new heights requires harnessing the power of advanced tools that offer unparalleled precision. One such tool is the high-definition LED light board, which provides enhanced visibility of the dent’s contours and imperfections. With this tool, technicians can better assess the damage and accurately plan their repair approach.

Furthermore, the advent of specialized blending hammers and knockdowns has revolutionized dent removal. These tools allow technicians to delicately manipulate the metal from the inside, gradually coaxing it back to its original shape without damaging the paintwork. The addition of interchangeable tips and adjustable handles ensures optimal control and versatility for various dent types.

II. Advanced Techniques for Complex Dent Restoration

Elevating PDR involves mastering advanced techniques that address even the most challenging dent restorations. One such technique is the “glue pulling” method, where technicians utilize high-strength glue and a pulling tab system to gently extract the dent from the exterior. This technique is particularly effective for larger or creased dents, providing excellent results while minimizing the need for conventional repairs.

Additionally, the art of “reverse tapping” has gained prominence in advanced PDR. This technique involves applying precise taps to the undamaged area surrounding the dent, effectively manipulating the metal and restoring the panel to its original shape. Reverse tapping requires skill, finesse, and an in-depth understanding of metal behavior, resulting in seamless dent repairs.

III. Innovations in Technology for Enhanced Efficiency

The integration of technology has revolutionized the PDR landscape, streamlining processes and enhancing efficiency. Advanced imaging systems, such as digital dent scanners, allow technicians to capture high-resolution images of the damaged area. These images can be analyzed on a computer screen, providing accurate measurements and assisting technicians in planning their repair strategy with utmost precision.

Moreover, the use of computer-aided design (CAD) software in PDR has transformed the way technicians approach complex dent restorations. With CAD software, technicians can digitally map the dent, simulate repair techniques, and generate a step-by-step plan, ensuring optimal outcomes. This innovative approach enhances efficiency, reduces guesswork, and results in precise dent repairs.

IV. Continuing Education and Professional Development

To truly take PDR to the next level, technicians must commit to lifelong learning and professional development. Attending industry conferences, workshops, and training programs dedicated to advanced PDR techniques allows technicians to stay updated with the latest tools, technologies, and methodologies. Collaborating with industry experts and fellow technicians fosters knowledge exchange and promotes growth within the PDR community.

Additionally, certification programs offered by reputable organizations provide recognition of a technician’s expertise in advanced PDR. Achieving certifications not only enhances professional credibility but also instills confidence in customers seeking top-notch dent repairs.

Conclusion

By embracing advanced tools, mastering intricate techniques, and leveraging innovative technologies, PDR technicians can elevate their craft to new heights of excellence. With precision tools offering unparalleled control, advanced techniques enabling the restoration of complex dents, and technology streamlining processes, flawless paintless dent repairs become an achievable goal.

However, it is essential for technicians to commit to continuous education and professional development to stay at the forefront of this rapidly evolving field. By embracing advanced tools, refining techniques, and pursuing ongoing growth, PDR technicians can offer unparalleled results, ensuring customer satisfaction and establishing themselves as leaders in the art of paintless dent repair.

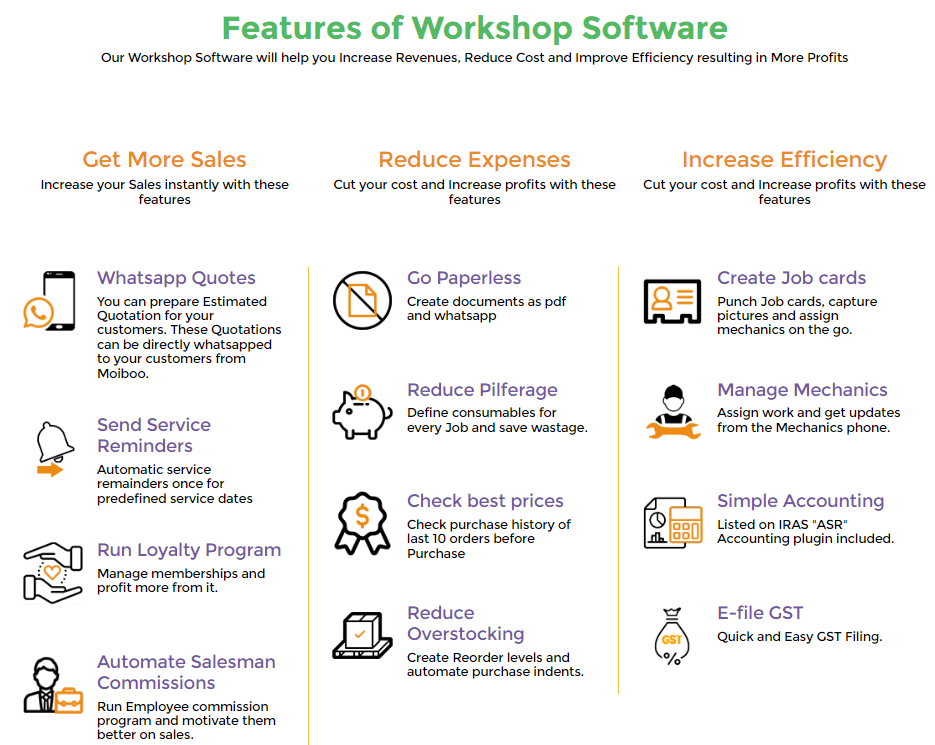

Revolutionize your automotive workshop with Moiboo Workshop Software, the ultimate solution that qualifies for the Productivity Solutions Grant (PSG). Designed to meet the unique needs of your business, this comprehensive software seamlessly integrates a wide range of features to boost productivity and streamline operations.

Increase the efficiency of your automotive workshop with Moiboo Workshop Software, a solution that automates and simplifies complex tasks. This user-friendly software enables you to effortlessly handle bookings, schedule appointments, track inventory, and generate invoices.

By automating these processes, you can save time, reduce errors, and redirect your focus toward revenue-generating activities that propel your business forward. With Moiboo Workshop Software streamlining your operations, you can optimize productivity and maximize your business’s growth potential.

Experience firsthand how Moiboo Workshop Software can transform your workshop operations and propel your business to new heights. Request a free demo today and unlock the full potential of this powerful software. Our team of experts will guide you through its functionalities, providing a clear understanding of how it optimizes your workflow and contributes to revenue growth.

What’s more, Moiboo Workshop Software has received pre-approval for the PSG Grant, simplifying the application process for your workshop. This pre-approval ensures that the software meets the grant’s requirements, giving you peace of mind and allowing you to maximize its benefits effectively.

To schedule your free demo or inquire further, please contact us at +65 9895 1817. Our dedicated team is committed to helping you streamline workshop operations, maximize revenue, and leverage the opportunities provided by the PSG Grant. Don’t miss out on this chance to elevate your automotive workshop to new heights of success.

FAQ:

Paintless Dent Repair is the best way to remove dents.

Paintless Dent Repair (PDR) is widely considered the best method for removing dents from vehicles. This technique utilizes specialized tools and techniques to massage the metal back into its original shape, eliminating the need for sanding, filling, or repainting.

Paintless Dent Repair is cost-effective, preserves the vehicle’s factory finish, and maintains its structural integrity. It is highly efficient for minor to moderate dents, offering impressive results while minimizing repair time and costs.

However, the suitability of Paintless Dent Repair depends on the specific dent and its characteristics, so consulting with a PDR specialist is recommended for an accurate assessment.

Overall, PDR stands out as the preferred choice for dent removal, providing exceptional outcomes and a seamless restoration of the vehicle’s appearance.